продукц

- ▶ Titanium product center

- ■ Titanium plate

- ■ Titanium tube

- ■ Titanium rod

- ■ Titanium forgings. Flange

- ■ Titanium alloy

- ■ Titanium, nickel, zirconium material

- ■ Titanium standard

- ■ Titanium workpiece

- ■ Titanium, nickel equipment

- ▶ Nickel product center

- ■ Nickel-based alloy

- ■ Nickel tube

- ■ Nickel plate

- ■ Nickel rod

- ▶ Titanium agitator

- ■ Titanium reactor agitator

- ■ Titanium stirring blade

- ▶ Industrial instruments/sensors

- ■ Industrial instrument

- ■ Industrial sensor

- ■ Pressure instrument

- ■ Non-standard sensor

产品介绍

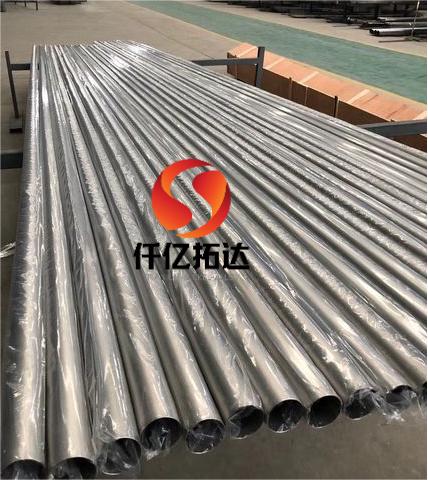

718 Inconel Alloy Tube

Specification:ASTM B163, B516 / ASME SB163, SB516

Dimensional specification:ANSI/ASME B36.19M, ANSI/ASME B36.10M

Seamless Tube Size:1 / 2" NB - 16" NB

Welded Tube Size:1 / 2" NB - 24" NB

Description

INCONEL alloy 718 (UNS N07718/W.Nr. 2.4668) is a high-strength, corrosion-resistant nickel chromium material used at -423° to 1300°F. Alloy 718 nickel tubing is an age-hardenable nickel-chromium-iron alloy also containing significant amounts of niobium, molybdenum, titanium and aluminum. It combines good corrosion resistance with extremely high strength. Typical applications include heat exchangers and O-rings.

|

Specification |

ASTM B163, B516 / ASME SB163, SB516 |

|

Dimensional specification |

ANSI/ASME B36.19M, ANSI/ASME B36.10M |

|

Seamless Tube Size |

1 / 2" NB - 16" NB |

|

Welded Tube Size |

1 / 2" NB - 24" NB |

|

Specialized in |

Large Diameter Size |

|

Schedule |

SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

|

Form |

Round, Hydraulic Etc |

|

Type |

Seamless / ERW / Welded / Fabricated / LSAW Pipes |

|

Length |

Single Random, Double Random & Cut Length. |

|

End |

Plain End, Beveled End, Threaded |

|

Delivery Condition |

Annealed and Pickled, Polished, Bright Annealed, Cold Drawn |

|

Value Added Services |

Cutting, Beveling, Polishing, Threading, Destructive, Non Destructive, Ultrasonic Testing |

Equivalent Grades

|

STANDARD |

WERKSTOFF NR. |

UNS |

|

Inconel 718 |

2.4668 |

N07718 |

Chemical Composition

|

Grade |

C |

Mn |

Si |

P |

S |

Ni |

Cr |

B |

Mo |

Co |

Al |

Ti |

Nb |

Cu |

|

Inconel 718 |

0.08 max |

0.35 max |

0.35 max |

0.015 max |

0.015 max |

50 – 55 |

17 – 21 |

0.006 max |

2.8 – 3.3 |

1.0 max |

0.2 – 0.8 |

0.65 – 1.15 |

4.75 – 5.5 |

0.3 max |