продукц

- ▶ Titanium product center

- ■ Titanium plate

- ■ Titanium tube

- ■ Titanium rod

- ■ Titanium forgings. Flange

- ■ Titanium alloy

- ■ Titanium, nickel, zirconium material

- ■ Titanium standard

- ■ Titanium workpiece

- ■ Titanium, nickel equipment

- ▶ Nickel product center

- ■ Nickel-based alloy

- ■ Nickel tube

- ■ Nickel plate

- ■ Nickel rod

- ▶ Titanium agitator

- ■ Titanium reactor agitator

- ■ Titanium stirring blade

- ▶ Industrial instruments/sensors

- ■ Industrial instrument

- ■ Industrial sensor

- ■ Pressure instrument

- ■ Non-standard sensor

产品介绍

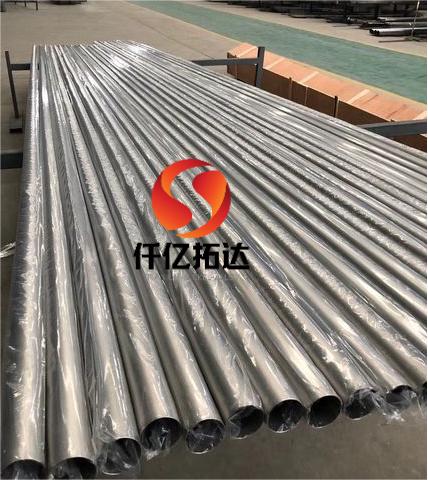

600 Inconel Alloy Tube

Specification:ASTM B163/ ASME SB163

Dimensional specification:ANSI/ASME B36.19M, ANSI/ASME B36.10M

Payment way:T/T, L/C, can be negotitated

Description

INCONEL Alloy 600 (UNS N06600 W.Nr. 2.4816) is a standard engineering material for applications which require resistance to corrosion and heat. The alloy also has excellent mechanical properties and presents the desirable combination of high strength and good workability. The versatility of INCONEL alloy 600 has led to its use in a variety of applications involving temperatures from cryogenic to above 2000°F (1095°C).

|

Specification |

ASTM B163/ ASME SB163 |

|

Dimensional specification |

ANSI/ASME B36.19M, ANSI/ASME B36.10M |

|

Seamless Tube Size |

1 / 2" NB - 16" NB |

|

Welded Tube Size |

1 / 2" NB - 24" NB |

|

Specialized in |

Large Diameter Size |

|

Schedule |

SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

|

Form |

Round, Hydraulic Etc |

|

Type |

Seamless / ERW / Welded / Fabricated / LSAW Pipes |

|

Length |

Single Random, Double Random & Cut Length. |

|

End |

Plain End, Beveled End, Threaded |

|

Delivery Condition |

Annealed and Pickled, Polished, Bright Annealed, Cold Drawn |

|

Value Added Services |

Cutting, Beveling, Polishing, Threading, Destructive, Non Destructive, Ultrasonic Testing |

Equivalent Grades

|

STANDARD |

WERKSTOFF NR. |

UNS |

JIS |

BS |

GOST |

AFNOR |

EN |

|

Inconel 600 |

2.4816 |

N06600 |

NCF 600 |

NA 13 |

МНЖМц 28-2,5-1,5 |

NC15FE11M |

NiCr15Fe |

Chemical Composition

|

Cu |

Ni |

Fe |

Mn |

C |

S |

Si |

Cr |

|

0.5 max |

72.0 min |

6.0 – 10.0 |

1.0 max |

0.15 max |

0.015 max |

0.5 max |

14.0 – 17.0 |