продукц

- ▶ Titanium product center

- ■ Titanium plate

- ■ Titanium tube

- ■ Titanium rod

- ■ Titanium forgings. Flange

- ■ Titanium alloy

- ■ Titanium, nickel, zirconium material

- ■ Titanium standard

- ■ Titanium workpiece

- ■ Titanium, nickel equipment

- ▶ Nickel product center

- ■ Nickel-based alloy

- ■ Nickel tube

- ■ Nickel plate

- ■ Nickel rod

- ▶ Titanium agitator

- ■ Titanium reactor agitator

- ■ Titanium stirring blade

- ▶ Industrial instruments/sensors

- ■ Industrial instrument

- ■ Industrial sensor

- ■ Pressure instrument

- ■ Non-standard sensor

产品介绍

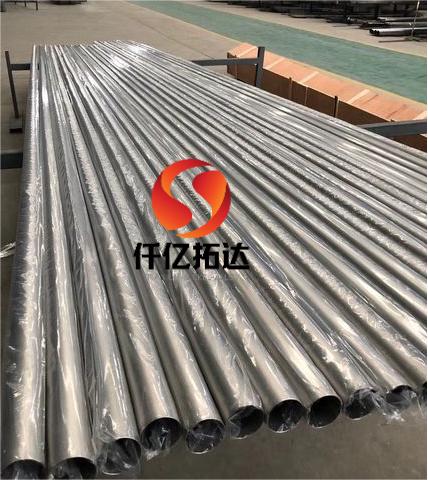

825 Incoloy Alloy Tube

Standard:ASTM B423, ASTM B163, ASTM B704

Outside Diameter:6.0-114 mm

Wall Thickness:0.5-15 mm

Length:Max.24000mm (the maximum length is for the scope of special diameters and walls)

Description

825 Incoloy Alloy Pipe is a high-performance nickel-iron-chromium alloy that is highly resistant to oxidation, corrosion and stress cracking. This type of pipe is widely used in the chemical processing and petrochemical industries, where it can withstand high temperatures and pressure.

One of the most popular forms of 825 Incoloy Alloy is the pipe type. The incoloy 825 pipe is manufactured in accordance with the ASTM B423 UNS N08825 standard, which ensures that it meets the industry's highest quality standards. This means that the pipes are robust, durable and can withstand extreme environmental conditions, making them ideal for use in various applications.

There are various types of 825 Incoloy Alloy pipes available in the market, including seamless, welded, and ERW types. The seamless pipes are ideal for high-temperature applications, while the welded and ERW types are preferred for low-temperature applications. The type of pipe you choose will depend on the specific application you need it for.

|

Product Name |

Incoloy 825 alloy tube |

|

||||

|

Standard |

ASTM B423, ASTM B163, ASTM B704 |

|

||||

|

Outer diameter |

6-114mm |

|

||||

|

Thickness |

0.5-15mm |

|

||||

|

Type |

Seamless and welded |

|

||||

|

Delivery Condition |

hot-finished annealed, cold-worked annealed, hot-forming quality (hot-finished or cold-drawn annealed) |

|

||||

|

Finish |

Ground, Pickled, Annealed |

|

||||

|

Test |

Mechanical Properties, Flattening Test, Flange Test, Eddy Current Test, Ultrasonic Test, Hydrostatic or Pneumatic Test, |

|

||||

|

Package Method |

Wooden case, and Customer requirements |

|

||||

|

Payment way |

T/T, L/C, can be negotitated |

|

||||

|

Transportation |

Sea(FCL/LCL), airplane, express(TNT/DHL/FEDEX) |

|

||||

|

Port |

Shanghai,Tianjin,Qingdao |

|

||||

|

Certificate |

EN10204 3.1/3.2,Third Party Inspection Report, etc |

|

||||

Equivalent Grades for Incoloy 825 alloy tube

|

GENERIC TERM |

DIN/EN |

UNS NO |

GB |

|

Incoloy 825 |

2.4858 |

UNS N08825 |

0Cr21Ni42Mo3Cu2Ti |

Physical Properties according to ASTM B423

|

Standard |

Density |

Melting Point |

Tensile Strength Rm N/mm2 |

Yield Strength (0.2%Offset) RP0.2N/mm2 |

Elongation A5 % |

|

ASTM B423 |

8.14g/cm 3 |

1370℃- 1400℃ |

MPa – 586 |

MPa –241 |

30 % |

Chemical Composition

|

Chemical Composition Limits |

|||||||||||

|

Weight % |

Ni |

Fe |

Cr |

Mo |

Cu |

Ti |

C |

Mn |

S |

Si |

Al |

|

Alloy 825 |

38-46 |

22min |

19.5-23.5 |

2.5-3.5 |

1.5-3 |

0.6-1.2 |

0.05max |

1max |

0.03max |

0.5max |

0.2max |

ALLOY 825 can be used in a variety of applications.

- Fuel element dissolvers

- Sea-water-cooled heat exchangers; offshore product piping systems; tubes and components in sour gas service

- Heat exchangers, evaporators, scrubbers, dip pipes etc. in phosphoric acid production

- Air-cooled heat exchangers in petroleum refineries

- Chemical and Food Processing

Ms. Vivian (王宁宁)Sales Manager

Shaanxi Qianyi Tuoda Technology Co., Ltd

Email:qy002@sxqytd.com

Phone/WhatsApp/ Wechat: +8618829679311

Address: Building 4, Hi-tech Development Zone,

Baoji City, Shaanxi Province, China

Website:www.sxqytd.com

Titanium Metal, Nickel Metal, Titanium Sheets, Titanium Tubes, Titanium Bars, Titanium Wire, Titanium Ingots, Nickel Sheets, Nickel Tubes, Nickel Bars, Titanium Alloys, Nickel Alloys, Titanium Fasteners, Titanium Jewelry