About Us

- Company Profile

- Corporate Culture

- Introduction to Titanium Alloy

- Introduction to Titanium Tube

- Introduction to Titanium Rod

- Introduction to Titanium Plate

- Introduction to Nickel Tube

- Introduction to Nickel Plate

- Introduction to Nickel Alloy

- Introduction to Titanium Stirrer

- Application of titanium agitator

- Industrial mixer

- Introduction to pressure instruments

- Introduction to Sensors

Shaanxi Qianyi Tuoda Technology Co., Ltd.

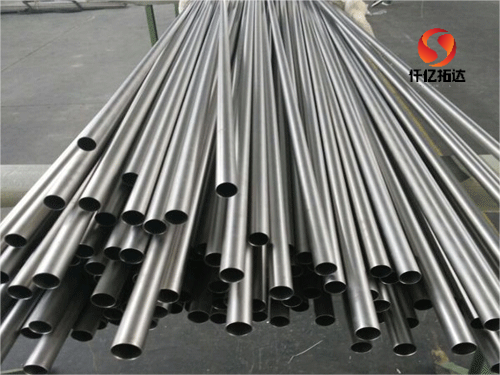

Titanium tube introduction:

Titanium pipe is a kind of advanced metal pipe with excellent performance and wide application fields. In my 30 years of experience in the titanium tube industry, I have a deep understanding of all aspects of this outstanding material. The following is a comprehensive introduction to titanium tubes:Production process:

The manufacturing process of titanium tubes is strictly controlled, including raw material extraction, refining, alloying and forming. State-of-the-art technologies ensure high purity titanium, including the gas oxidation process, the Kroll process and others. Subsequently, the initial shape of the titanium tube is formed by forging, extrusion or seamless rolling, and finally it is made to reach the required size and performance through heat treatment and cold working.

Specifications:

The specifications of titanium tubes vary from application to application, and common specifications include diameter, wall thickness, length, etc. Its specifications can be customized according to customer needs, ensuring that the specific requirements of various engineering projects are met.

Different from other pipes:

Compared with other pipes, such as stainless steel, copper, etc., titanium pipes have excellent corrosion resistance, high strength-to-weight ratio, and high temperature resistance. This makes titanium tubes perform better in some special fields, such as aerospace, medical devices, and so on.

Purpose:

Titanium tubes are widely used in aerospace, chemical, medical, ocean engineering and other fields. In aerospace, because of its characteristics of light weight and high strength, it is widely used in aircraft structures. In the medical field, titanium tubes are often used to make bone repair devices.

Market demand:

With the continuous development of high-tech, the demand for high-performance metal materials is also increasing. Because of its unique performance, the demand for titanium tubes in the market continues to grow steadily, especially in the rapid rise of applications in emerging fields.

Breed:

There are many varieties of titanium tubes, including seamless titanium tubes, welded titanium tubes, thin-walled titanium tubes, etc., to meet the requirements of different engineering projects on the performance and shape of the pipes.

Inspection during production:

In the production process of titanium tubes, strict quality control and inspection is the key to ensure product quality. Through ultrasonic detection, X-ray detection and other advanced non-destructive testing means, to ensure that the titanium tube is flawless and in line with standards.

Welding:

The welding of titanium tube is a complicated and critical link. Using inert gas shielded welding, electron beam welding and other highly controlled welding technology to ensure the quality of the weld and the overall performance of the titanium tube.

Surface treatment:

The surface treatment of titanium tubes usually includes pickling, polishing and other processes to ensure its surface finish and corrosion resistance.

Mechanical properties and chemical composition of TA2 titanium tube:

TA2 is a commonly used industrial pure titanium with good weldability and cold deformation. Its mechanical properties include strength, elongation, etc., and the chemical composition is mainly composed of iron, oxygen, carbon and other elements, with excellent corrosion resistance.

In general, titanium pipes, as an outstanding metal pipe, play an irreplaceable role in various fields. Through continuous innovation and improvement of the production process level, we can better meet the market demand and promote the development of the titanium tube industry.

Titanium seamless tube:

Titanium seamless pipe is a high-strength, lightweight and corrosion-resistant pipe suitable for a variety of industrial applications requiring high purity and superior performance.

Titanium alloy tube:

Titanium alloy tubes have excellent strength and corrosion resistance, and are widely used in aerospace, medical devices and chemical industries.

Titanium TA2 tube:

Titanium TA2 tube material has excellent welding and mechanical properties, is an economical and practical engineering material, often used in the manufacture of various equipment and structures.

Applications of titanium tubes in the field of aviation:

Because of its lightweight and high-strength characteristics, titanium tubes are widely used in the aviation field to manufacture aircraft structures and engine components.

Titanium tube applications in the medical field:

Titanium tubes play an important role in the manufacture of medical devices, such as artificial joints, dental implants, etc., and are favored for their biocompatibility and corrosion resistance.

The application of titanium tubes in Marine engineering:

Titanium tubes have the characteristics of resistance to seawater corrosion, so they are used in the field of Marine engineering to manufacture seawater desalination equipment and offshore platform structures.

Titanium tube in chemical engineering uses:

Titanium pipes are widely used in chemical engineering, especially in acid and alkali environments, and their corrosion resistance makes them an ideal choice for pipes.

Titanium tube in the field of energy applications:

Titanium tubes are used in the energy industry to manufacture oil, gas and nuclear power equipment due to their superior performance in high temperature and corrosive environments.

The application of titanium tubes in the automotive industry:

Titanium tubes are lightweight and strong, suitable for automotive manufacturing, can reduce vehicle weight, improve fuel efficiency.

High temperature application of titanium tube:

Titanium tubes perform well in high temperature environments and are widely used in the manufacture of heat exchangers, boilers and other high temperature equipment.

Low temperature application of titanium tube:

Titanium tubes have excellent frost resistance at low temperatures and are suitable for manufacturing liquefied natural gas (LNG) equipment and aerospace devices.

Electronic applications of titanium tubes:

Titanium tubes are used in the electronics industry to manufacture battery casings, semiconductor devices, and other electronic devices to ensure high purity and stability.

Titanium tube for food industry applications:

Titanium tubes are widely used in the food industry to manufacture food processing equipment because they are odorless, non-toxic and do not produce any harmful substances.

Titanium tube in the field of construction applications:

Titanium tubes are used in the construction field to make Bridges, stair railings, decorative materials, etc., bringing light weight and durability to buildings.

The application of titanium tube in petrochemical industry:

Titanium tubes play a key role in the petrochemical industry and are used in the manufacture of pressure vessels, heat exchangers and chemical pipelines.

Environmental applications of titanium tubes:

Because of its recyclability and environmental protection characteristics, titanium tubes are widely used in the manufacture of environmental protection equipment, such as waste gas treatment devices.

Nuclear industry applications of titanium tubes:

Titanium tubes are used in the nuclear industry to manufacture nuclear reactor components and have excellent radiation resistance and high temperature properties.

The application of titanium tubes in shipbuilding:

Titanium tubes are often used in shipbuilding to manufacture hull structures and seawater treatment systems because of their resistance to seawater corrosion.

The application of titanium tubes in aerospace devices:

Titanium tubes are used in aerospace devices to make missile casings, satellite structures, etc., because of their light weight and high strength.

The application of titanium tubes in the power industry:

Titanium tubes are used in the power industry to manufacture thermal power plant boilers and transmission lines because of their corrosion resistance and high temperature properties.

The application of titanium tube in sanitary engineering:

Titanium tubes are used in sanitary engineering to make pipes, valves and other sanitary equipment because of their easy cleaning and corrosion resistance.

The application of titanium tubes in vehicles:

Titanium tubes are widely used in the manufacture of vehicles, such as bicycles, motorcycles and ships, to improve lightweight and strength.

The application of titanium tubes in the anti-corrosion industry:

Because of its excellent corrosion resistance, titanium pipes are often used in anti-corrosion engineering, such as Bridges, tunnels and water treatment facilities.

The application of titanium tubes in the cosmetics industry:

Titanium tubes are used in the cosmetics industry to manufacture high-end cosmetic packaging because of its light weight, easy discoloration and no harmful substances.

Titanium tube in the textile industry:

Titanium tubes are used in the textile industry to manufacture textile machinery components due to their corrosion resistance and high temperature stability.

Titanium tube in the glass industry:

Titanium tubes are used in the glass industry to make glass furnace components because of their resistance to high temperatures and corrosion.

The application of titanium tube in electroplating industry:

Titanium tubes are often used in the electroplating industry to make corrosion-resistant plating tanks and electrodes.

Titanium tube in the military field of application:

Titanium tubes are used in the military industry to manufacture military aircraft, missiles and other defense equipment because of their high strength and corrosion resistance.

The application of titanium tube in furniture manufacturing:

Titanium tubes are used in furniture manufacturing to manufacture structural components of high-end furniture due to their light weight and durability.

The application of titanium tube in architectural decoration:

Titanium tubes are often used in architectural decoration, such as handrails, railings and decorative structures, because of their texture and corrosion resistance.